美国留学申请文书——ME-制造 PS

2017-04-05 256阅读

Through my undergraduate’s study, I realize that manufacturing is the foundation of national economy and national dense, and one important development direction of manufacturing is ultraprecision machining and even nanometer machining, which is the core of manufacturing. With development of computer, the application of computer control technology in manufacturing field more and more widely, which greatly improves manufacturing technology. The size of workpiece in manufacturing develops toward two directions: one is large and super large; the other is minimization, even nanometer machine. Moreover, as other technologies develop, many new special machining methods in manufacturing field, like Rapid Prototyping and Manufacturing and long-distance machining, which are new and fresh for me.

After the summer holidays of 2005, I designed a new type of torsion spring in the research on measuring the moment of inertia of large quality (measuring the equatorial and the polar rotational inertia). The new type of torsion spring consists of two ring flanges and a group of long and thin plates, which are perpendicular to the flanges and taken as reinforcement plates of spring. Two ring flanges are parallel to each other in space and there is a distance between them. This distance is the length of the reinforcement plates. Between two flanges, the reinforcement plates are fixed symmetrically and symmetrical axis is connection line of two flanges centers. Two ends of each reinforcement plate are fixed on the inside face of the flanges. This spring possess high axial stiffness, high radial stiffness and high torsion softness, so it assured the measurement accuracy and made the research progress successfully. With my teachers’ support, I have applied for invention paten, which has been publicly notified and is going to take fect. The successful experience makes me more confident and strengthens my determination to study further in this field.

Thought the experiment was about the measurement of moment of inertia for a large body, I found the key point of this project is not measurement, but the design of measurement system. According to current technology, a spiral spring or a bar spring is directly used as torsion spring, but it is very difficult to measure moment of inertia for a large body accurately by them. For a large body, the requirements for the axial and radial stiffness, intensity and stability of spring must be high. In order to meet the requirements, the section size must be increased, which would increase the rigidity, intensity and stability of spring but restrict its flexibility. In order to improve axial and radial stiffness, intensity and stability as well as keeping flexible, I read a lot of related materials, discussed with the research group and the lab instructor, and consulted my father. At the beginning, everyone was limited to designing a spring, which can solve both problems, but failed. I thought about other structures and , after trying many different kinds, I invented a new type of torsion spring, which combines several elastic distortion elements together to form a combined torsion spring. The elastic distortion elements are a group of long and thin plates, which are called as reinforcement plate can be reduced to a minimum, which keeps the spring flexible enough and solves the key problem of the project. By test, it turns out that the torsion spring not only possesses a high flexibility, but also very high axial and radial stiffness, which solved our problems satisfactory.

In our research, I designed the whole measurement system with AUTOCAD and made the key part, torsion spring, into 3D by CATIA. From the experiment, I learned benchwork skills and improved my operation ability further.

The satisfying experiment result should be attributed to my family’s influence. My father formerly was the dean of school of mechanical engineering in Changchun University of Science and Technology. When I was five, I father took me to his experiment where I first got in touch with machine manufacturing. When I saw a worker turning a bar into a beautiful cone, I generated deep interests. With my father’s instruction, I learned how to design simple blueprint with AUTOCAD and made out actual workpiece according to the blueprint in high school, which made me feel successful and inspired me a lot.

Engineering is a subject with strong practicality. In order to improve my operational ability, in the first semester of my junior year, I joined in the precision machining lab to participate in high speed lapping research. We tried to change lapping pressure; speed and abrasives size to study their influence on surface hardening of work. My main task was to process and measure samples. We found that, with the increasing of abrasive size, the workpiece surface becomes harder after being lapped by solid-abrasive, but which is not obvious. The surface hardness of workpiece would be strengthened as lapping pressure is increased. As the lapping speed increased, the surface hardness of workpiece increases obviously. According to equal fect principle of plastic dormation work, hardening results lies on total plastic dormation work produced in distortion. When lapping speed is increased, the fect of dormation delay increases the stress on workpiece and the work consumption on producing plastic dormation, which results in serious hardening. According to the research work I have done, I published the paper “The research of Hardening of high-speed lapping surface”.

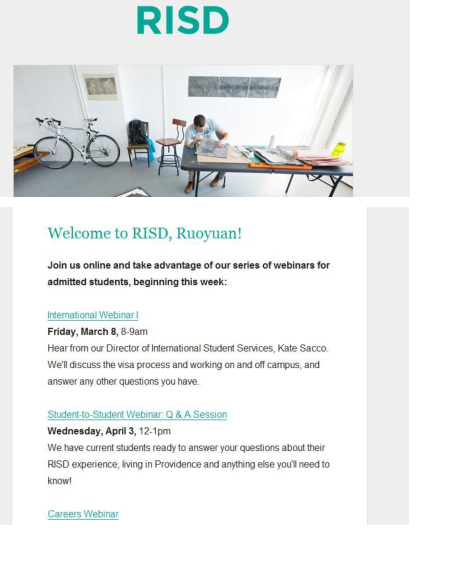

Since I become more and more interested in manufacturing, I hope to study further in this field. In the University of Southern California, there are a lot of famous professors who are doing forward research in this field, who can realize my dream of studying the most advanced technology. I notice that the University of Southern California is doing research on Machine Learning, Design & Manufacturing Automation, which greatly attracts me. What’s more, the university has advanced scientific research equipment and technology. Therore, I am eager to study in your esteemed university.

叁陆零教育集团提示:PS是留学申请中重要的一部分,写作需要结合申请人自己的经历与特点进行书写,提醒广大学生只可参考,不可照抄。

立即咨询留学咨询

更多出国留学最新动态,敬请关注澳际教育手机端网站,并可拨打咨询热线:400-601-0022

留学热搜

相关推荐

- 专家推荐

- 成功案例

- 博文推荐

Copyright 2000 - 2020 北京澳际教育咨询有限公司

www.aoji.cn All Rights Reserved | 京ICP证050284号

总部地址:北京市东城区 灯市口大街33号 国中商业大厦2-3层

高国强 向我咨询

行业年龄 13年

成功案例 3471人

留学关乎到一个家庭的期望以及一个学生的未来,作为一名留学规划导师,我一直坚信最基本且最重要的品质是认真负责的态度。基于对学生和家长认真负责的原则,结合丰富的申请经验,更有效地帮助学生清晰未来发展方向,顺利进入理想院校。

陈瑶A 向我咨询

行业年龄 17年

成功案例 5146人

拥有大量高端成功案例。为美国哈佛大学、宾夕法尼亚大学等世界一流名校输送大批优秀人才。

齐亚楠 向我咨询

行业年龄 15年

成功案例 4070人

商科案例有哥伦比亚大学等,工科案例有麻省理工大学等,艺术案例有罗德岛大学等。

李君君 向我咨询

行业年龄 15年

成功案例 4157人

成功案例涉及美国排名前60的院校,专业涵盖商科(金融,会计,管理),工科(生物工程,化学工程,计算机科学,电气工程)等热门领域。